|

The G 600 Prep and Much More

The Radios Get wired and Mounted

The PMA 8000B, GNS 530W, SL-30, and GTX 330 get the normal wiring and mounting

treatment but the EDM 930 was never designed to be installed in a radio stack. Because it is a direct replacement for the primary Engine, Fuel, and Aircraft power monitoring system, it was meant to be installed in the instrument panel in place of the existing instrument cluster. Phil, however, wants it installed in the radio stack along with the rest of the equipment. Since the EDM is only 6" wide and there are no provisions for side rack mounting we had to do a little machining. The new mount had to contain the same parameters as standard radio racks do with 6.3" width to match the mounting rails and, of course, hold the unit in place.

The mount shown above ,when powder coated satin black and mounted in place with the 930 unit will protrude out the same distance as the face of the other radios in the stack for an even look.

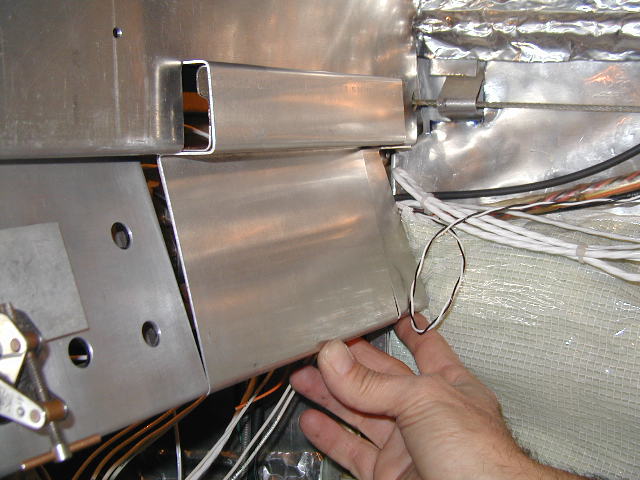

One wiring item worth mentioning is the lower switch and circuit breaker panels (REF the center photo). All of our power panels are fabricated this way for two reasons. First of all it makes the installation much easier if you can minimise the amount of time laying on you back under the instrument panel hooking up wires. This way all of the connections are brought into two CPC connectors as shown. Obviously all of the aircraft equipment this power and control is being routed to, is terminated in the mating connector. When everything is installed connecting power is a snap. It makes for a much cleaner installation when these wiring harnesses can be fabricated on the bench. Second of all, if a change to the breakers or switches is required, its simple to remove the jam nuts on the breakers, disconnect the interface connectors and drop the entire assembly out the bottom of the instrument panel. Not that happens very often, but if the need arises, its much easier to do that it is to modify the breaker configuration standing on your head.

One of the more challenging aspects of our panel fabrication is making the Glove box door. It is made from a single piece of aluminum, contains complex bends, and must line up with the upper and lower panels. This is where practice makes perfect. The door itself will get a two-tone powder coating with the upper handle being wrinkle gray and the lower portion being textured black.

Web site and all contents © Copyright Avionicswest.net, All rights reserved.

|